2023-03-09

Sealants are used in various construction applications. These uses include extending (reinstating gaps) from doors, window glazing, frames, and slab termination voids between curtain walls or metal cladding facades. Sealants are materials applied in an unformed state that, once cured or dried, has the adhesive and cohesive properties to seal a joint. It is defined by the UAE Fire and Life Safety Code of Practice as a product installed to allow thermal expansion and contraction of different cladding components and prevent moisture penetration. Sealants are always up to the task anywhere there is a need to fill and block gaps or provide an impermeable layer to protect inner surfaces. Sealants are rarely given the consideration they require. Still, these are components essential to safeguard the building from challenges of the external complexities of the climate, environment, and fire.

A façade material may delaminate during a fire, exposing the core and cladding system. If the sealant is combustible, the flame may start spreading along the surface of the façade, resulting in a sudden engulfing of a vast area and multiple stories under fire. With this, the code has specified the minimum requirements for the classification, combustibility, surface burning and flame spread ratings, design, installation, inspection, and maintenance of exterior façade wall claddings and its components, such as sealants.

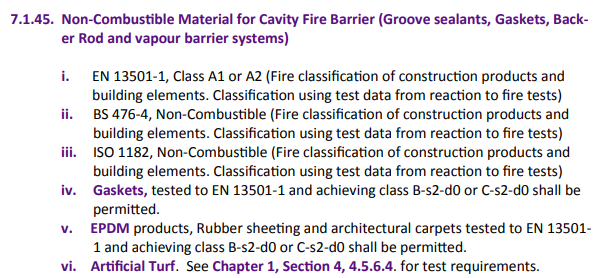

The use of flammable silicon or fillers or non-rated groove sealants, materials in between panel joints is not permitted unless these joint fillers are tested based on Section 7.1.45 of the UAE Fire and Life Safety Code and part of their complete wall assembly were used in achieving “pass criteria” as the wall assembly “Large Scale Tests”.

How are sealants tested? One of the acceptable methods is the European Standards (EN) 13501-1. The classification EN 13501-1 standard revolves around the EN 13823 or Single Burning Item (SBI) test, an intermediate-scale test method to measure heat and smoke release rate, lateral flame spread and flaming droplets. If the sealant is to be proven to be classified as either A2 or B class, there will be a need to satisfy the system requirements of the EN 13823 test.

For the SBI test, a specimen consisting of two vertical wings forming a right-angled corner is exposed to the flames from a burner placed at the bottom of the corner, known as the “main (primary) burner”. The flame source is obtained by the combustion of propane gas, diffused through a sandbox giving a heat output of 30 kW. The performance of the test specimen is evaluated over a period of 20 min.

A linear product like a sealant to be tested in the single burning item rig shall be mounted and fixed to simulate its end-use condition, as specified in EN 13823, clause 5.2.1 (test according to the intended use), not clause 5.2.2 (standard mounting and fixing). Many linear products can be tested per a specific EN standard or the European Group of Organisations for Fire Testing, Inspection and Certification (EGOLF) Agreement. Sealants follow EGOLF recommendation “005-2019 - Testing linear products in the SBI” specimen preparation.

Sealants shall be mounted in the long wing, as showed in below figure, and shall be fixed, creating three joints, two with the following measures: 20mm x 10mm x 1500mm and one: 20mm x 10mm x 1000 mm (width x depth x length) as described in the standard EN 15651-2, this is the minimum width x depth. If the product is applied with a greater amount in the end-use conditions, that specific width x depth shall be used. Another seal of the same width x depth x length shall be mounted in the short wing at 100 mm from the edge.

Calcium silicate with a thickness of 20mm and a density of 870 ± 50 kg/m3 or any other substrate described in EN 13238 should be used as substrate. Linear density (kg/m) is considered an “influencing parameter”. If, in the end-use, the distance between two parallel sealants is less than 100 mm; another sealant shall be applied in the long wing and one in the short wing at 50 mm from the sealant mounted in the corner. This mounting is also representative of linear or pipe applications under end-use conditions.

The detailed specimen preparation may be checked from this link:

https://www.egolf.global/download/%7B87D3F46D-CB22-4233-B182-C9D2F76CEB1F%7D

The whole mechanism involved in façade flame spread must be evaluated; this extends to properly setting up components and accessories for testing. At ESL, in collaboration with UAE Civil Defence, we can advise you on the mounting and fixing method to best assess a product’s behaviour during a real-fire scenario.

With our team of technical experts, we can help you enhance the fire safety of your products.

Yes, We are here to help!